Scaffold roof sheets protect construction sites from weather. They are durable and handle water runoff well. This article explains why these sheets are important and how they benefit your projects.

Key Takeaways

- Scaffold roof sheets are vital in construction, providing durable protection against harsh weather, facilitating efficient drainage, and maximizing safety and performance.

- The sheets are made from high-quality galvanized steel, ensuring corrosion resistance and longevity, with customizable sizes available to meet specific project needs.

- Proper installation and regular maintenance are crucial for extending the lifespan of scaffold roof sheets, while various delivery options and transparent pricing are essential for effective project planning.

Scaffold Roof Sheets Overview

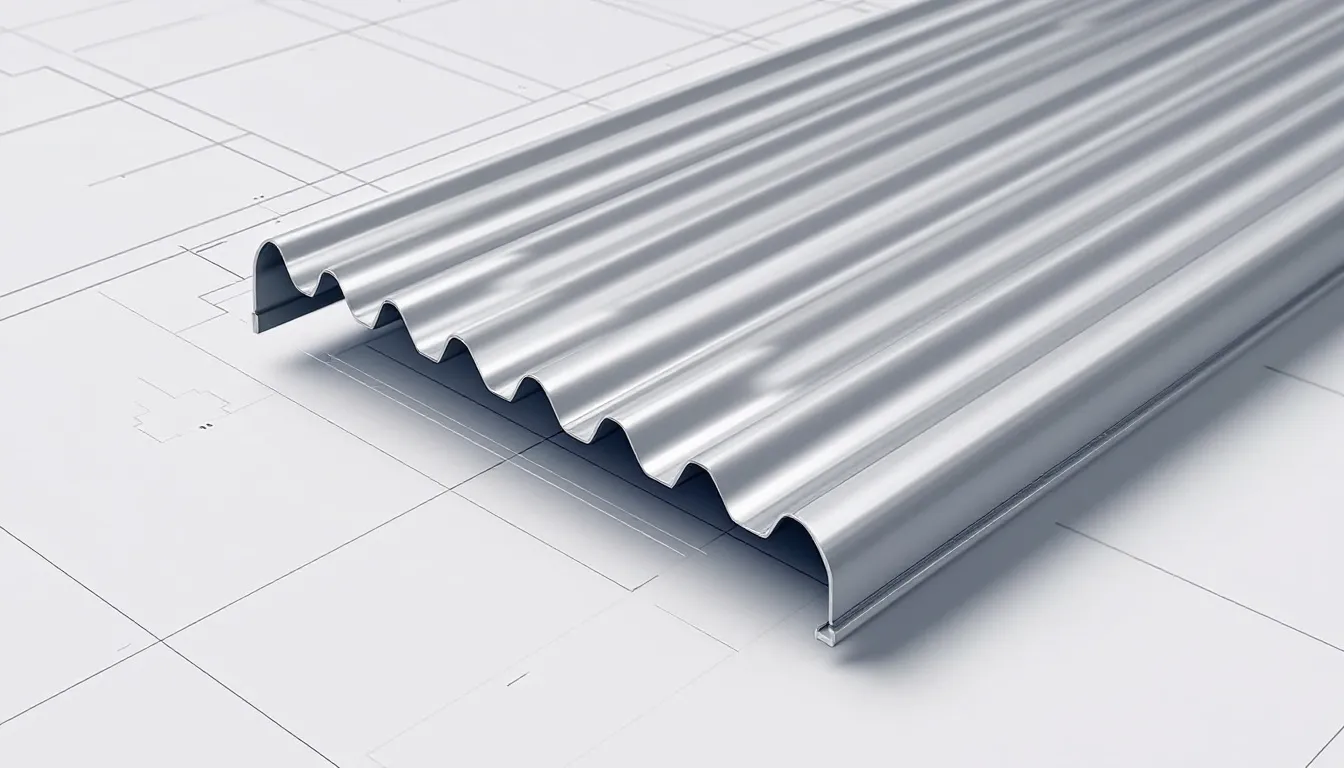

Scaffold roof sheets are essential in the construction industry, offering strength and effective water runoff to keep work sites protected from the elements. The grooves in corrugated steel roofing sheets enhance their structural integrity and facilitate efficient water drainage, preventing accumulation that could compromise the structure. Proper installation maximizes safety, performance, and the lifespan of these sheets.

These sheets are crafted to withstand harsh weather conditions, making them essential for temporary roofing applications. Whether it’s a small renovation project or a large-scale construction endeavor, scaffold roof sheets offer reliable protection against rain, wind, and other environmental factors. Correct positioning during installation optimizes their shielding ability, maintaining a secure working environment.

Scaffold roof sheets serve as a protective barrier, allowing construction activities to continue uninterrupted, regardless of weather conditions. These sheets provide a stable, secure covering, enhancing the safety and efficiency of construction projects, including scaffold sheeting.

Common Applications

Scaffold roof sheets are utilized across a wide range of sectors, each with its unique requirements and challenges that are commonly faced. In construction, these sheets protect work sites from adverse weather, ensuring projects proceed safely and efficiently, minimizing downtime and potential damage.

In the agricultural sector, these sheets are invaluable for covering livestock housing and protecting crops during harvest. They offer a practical solution to add safeguard agricultural equipment and produce from rain and other environmental elements, including barns, stock, and sheds.

In industrial settings, scaffold roof sheets cover machinery and materials, preventing weather-related damage and ensuring operational continuity.

Benefits of Using Scaffold Roof Sheets

A primary benefit of scaffold roof sheets is their robust protection against rain and wind, maintaining a secure working environment. Designed for easy installation, these sheets significantly reduce setup time on construction sites, enhancing project efficiency. Their ability to withstand harsh weather conditions further enhances their durability and reliability.

Moreover, the corrugated roofing sheet design of these sheets not only adds to their strength but also facilitates effective water runoff, preventing water accumulation that could potentially damage the underlying structure. This makes scaffold roof sheets an excellent choice for temporary roofing applications where durability and performance are paramount.

Material and Design

Scaffold roof sheets are predominantly crafted from high-quality galvanized steel, offering a robust and reliable solution for temporary roofing needs. The use of galvanized steel ensures that these sheets are durable and capable of withstanding harsh environmental conditions, providing long-term protection during construction projects. The thoughtful design of these sheets further enhances their efficiency and reliability.

Material choice and design features greatly impact scaffold roof sheet performance. Proper installation enhances their longevity, ensuring they remain effective throughout the project. By combining high-grade materials with intelligent design, scaffold roof sheets deliver exceptional performance in protecting construction sites.

Galvanised Finish

A galvanised finish on scaffold roof sheets is crucial for enhancing their resistance to corrosion and extending their operational lifespan. The zinc coating acts as a barrier against moisture, reducing the risk of rust and keeping the sheets in good condition for longer. This corrosion resistance is crucial in environments with varying weather conditions.

The galvanised coating not only protects the sheets from rust but also enhances their overall durability. This makes them an ideal choice for temporary roofing applications where reliability and longevity are critical. The galvanized finish prevents corrosion, ensuring scaffold roof sheets maintain structural integrity and provide effective protection.

Thickness and Strength

The thickness of scaffold roof sheets determines their strength and load-bearing capacity. Standard thicknesses for these sheets include options like 22g, 24g, and 26g, which contribute to their overall durability. Common thicknesses range from 0.5mm to 1.5mm, with thicker sheets providing improved durability and resistance to damage.

Choosing the right thickness for a specific application ensures optimal performance. Thicker sheets provide greater load resistance, suitable for environments with heavy loads or adverse weather conditions. By choosing the right thickness, you can enhance the structural integrity and longevity of your scaffold roof sheets.

Weight and Handling

A significant advantage of scaffold roof sheets is their lightweight construction, simplifying transportation and installation compared to heavier materials. Weighing between 5 to 10 kg per square meter, these sheets are manageable for handling and installation. This lightweight nature also reduces overall labor costs, as fewer workers are needed to install the sheets.

The ease of handling these lightweight sheets makes them a practical choice for various construction projects. By simplifying the installation process, scaffold roof sheets help to expedite project timelines and reduce the physical strain on workers. This, in turn, contributes to a safer and more efficient work environment.

Sizes and Customisation

Scaffold roof sheets are available in a variety of standard sizes, catering to a range of construction needs. Metal roofing sheets typically come in standard widths that cover one meter after lapping, with common lengths including 8ft (2.4m) and 10ft (3m). These standard sizes provide flexibility and convenience for various projects, ensuring that the sheets can be easily adapted to different requirements.

Customization options allow for ordering ci sheets to specific dimensions in addition to standard sizes. This ensures a perfect fit for unique construction needs, offering tailored solutions that enhance efficiency and effectiveness. Custom-sized sheets allow suppliers to meet the precise requirements of any project, regardless of complexity.

Standard Widths and Lengths

Metal roofing sheets are typically available in various standard sizes, including common widths of 1000mm and lengths up to 9 meters. The typical width for scaffold roof sheets is around 812mm, with an effective coverage width of approximately 762mm. These standard sizes accommodate a range of projects, from small-scale renovations to large construction endeavors.

A variety of standard sizes make scaffold roof sheets versatile and convenient for different applications. Whether for a temporary roof or to cover equipment, the available sizes ensure the right fit for your project. This flexibility meets the diverse needs of the construction industry.

Custom Cuts

Custom-sized sheets are essential for ensuring a perfect fit for any project. Ordering custom-sized sheets requires providing specific dimensions to ensure a precise fit. This involves detailing exact measurements and allowing for lead time before delivery.

Requesting custom-sized metal sheets tailored to specific project dimensions ensures optimal coverage and protection. This customisation enhances the overall effectiveness of the sheets and ensures that they meet the unique requirements of each construction project.

Installation and Maintenance

Proper installation and regular maintenance are vital for ensuring the efficiency and safety of scaffold roof sheets. Ensuring that the structure is stable and all sheets are securely fastened with appropriate fasteners is crucial for preventing accidents and extending their service life. Regular maintenance protects against weather damage and corrosion, ensuring long-term effectiveness.

Adhering to best practices for installation and maintenance maximizes the performance and long life of scaffold roof sheets. This enhances the safety and efficiency of your construction project and ensures the sheets provide reliable protection throughout their use.

Installation Tips

Designed to be lightweight, corrugated sheets facilitate easier transportation and installation on site. Generally, scaffold roof sheets weigh between 5 to 10 kg per square meter, making them manageable for installation. Start from one end and work across, overlapping each sheet to ensure proper coverage and prevent water ingress.

Securing the roof sheets correctly ensures their stability and performance. Use stitching screws to secure overlaps between sheets, ensuring they are fastened properly to prevent movement during adverse weather. Using appropriate safety equipment during installation is crucial to avoid accidents.

Maintenance Best Practices

Regular inspections for rust and damage are essential to maintain the lifespan of scaffold roof sheets. Inspecting the sheets for signs of wear or damage allows for early detection and prompt resolution of potential issues. Periodic cleaning removes debris that could cause corrosion, maintaining the sheets’ integrity.

Applying a protective coating extends the lifespan of scaffold roof sheets by enhancing their resistance to weather elements. Following these maintenance best practices ensures your scaffold roof sheets continue to provide reliable protection for your construction projects.

Delivery and Pricing

Understanding delivery and pricing options for scaffold roof sheets is crucial for efficient project planning. Delivery methods include direct shipping to the job site or collection from a local branch, with standard and express delivery options. Some suppliers offer next-day delivery, ensuring quick access to materials when needed urgently.

Pricing for scaffold roof sheets includes the base price, applicable VAT, and any additional shipping or handling fees. Base prices are typically listed excluding VAT, which is added at checkout. Additional charges may include delivery fees, often calculated based on distance.

Delivery Options

Customers can choose from various delivery methods to ensure timely product arrival, including standard and express options. Some suppliers offer same-day delivery for urgent orders, ensuring quick access to materials and enhancing project efficiency. Having a variety of delivery options ensures that customers can receive their scaffold roof sheets when they need them.

Offering a range of delivery options allows suppliers to cater to different customer needs and project timelines. This flexibility ensures construction projects proceed smoothly and without delays.

Price Breakdown

The total cost of roofing sheets includes the base price, applicable VAT, and any additional shipping or handling fees. Base prices for metal roofing sheets are typically listed excluding VAT, which is added at checkout. Additional charges may include delivery fees, often calculated based on distance.

Understanding the price breakdown helps customers plan their budgets and account for all costs associated with purchasing scaffold roof sheets. This pricing transparency aids in making informed purchasing decisions.

Contact Us

For questions or to place an order, please reach out to us. Contact us via our dedicated phone number or email address listed on our website. Our team is ready to provide additional information and support, ensuring you can handle all the resources you need in the form of your project at the centre.

Explore further resources on our website to enter additional information and support. Whether you need detailed product specifications or assistance with custom orders, our team is here to help every step of the way.

Summary

Scaffold roof sheets are an essential component in various sectors, including construction, agriculture, and industrial applications. Their robust design, featuring corrugated patterns for enhanced strength and water runoff, ensures that work sites remain protected from harsh weather conditions. With proper installation and regular maintenance, these sheets offer reliable and long-lasting protection, making them an indispensable asset for temporary roofing needs.

In conclusion, the benefits of scaffold roof sheets are multifaceted, offering durability, ease of installation, and versatility in applications. Whether you’re shielding a construction site, protecting agricultural produce, or covering industrial machinery, these sheets provide the necessary protection to keep your operations running smoothly. By choosing high-quality materials and following best practices in installation and maintenance, you can maximize the performance and lifespan of your scaffold roof sheets, ensuring they serve your needs effectively for years to come.

Frequently Asked Questions

What are scaffold roof sheets made of?

Scaffold roof sheets are primarily constructed from high-quality galvanized steel, ensuring durability and resistance to harsh weather conditions.

How do I ensure proper installation of scaffold roof sheets?

To ensure proper installation of scaffold roof sheets, it is essential to create a stable structure, overlap each sheet sufficiently to prevent water ingress, and use suitable fasteners for secure attachment. This will enhance safety and efficiency in your workplace.

What are the common applications of scaffold roof sheets?

Scaffold roof sheets are primarily utilized in construction for temporary roofing, as well as in agriculture for livestock housing and crop protection. They also serve in industrial environments to safeguard machinery and materials.

How do I maintain scaffold roof sheets?

To maintain scaffold roof sheets, regularly inspect them for rust and damage, clean them to remove debris, and apply protective coatings to enhance their weather resistance. Consistent upkeep is essential for prolonging their lifespan.

What delivery options are available for scaffold roof sheets?

Customers can choose from standard shipping, express services, and next-day delivery options for scaffold roof sheets, providing flexibility in receiving their orders promptly.